Quid factores afficiunt processus temporis et efficientiam CNC EDM mori mergit machinis?

2024.09.17

2024.09.17

News industria

News industria

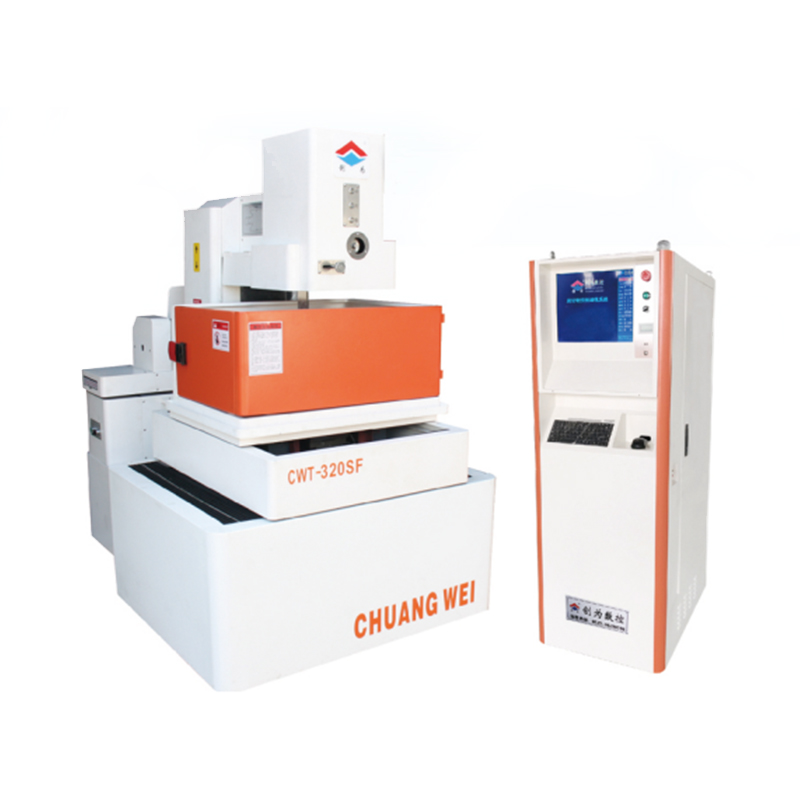

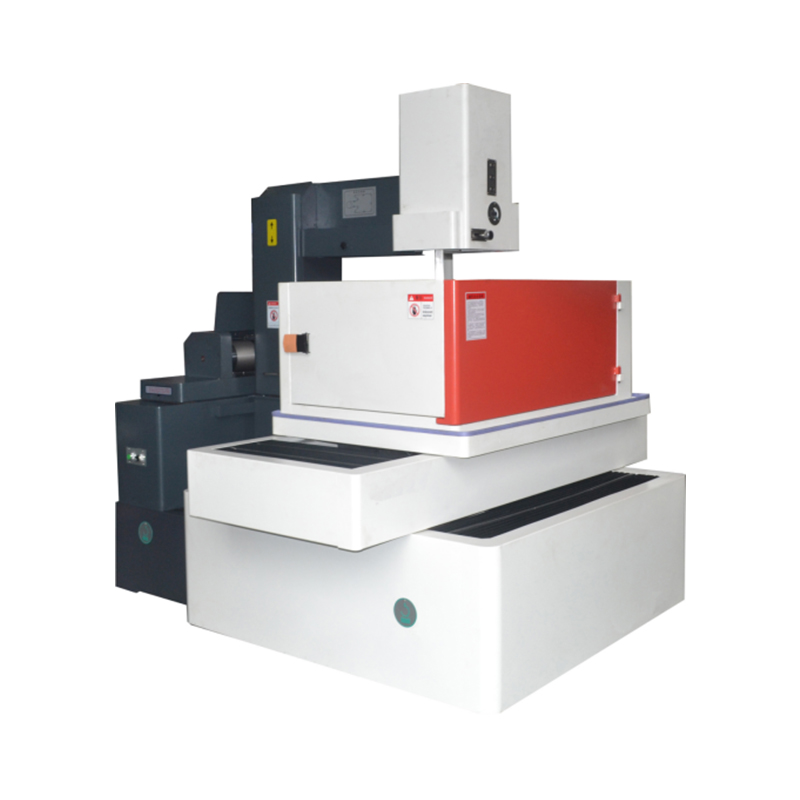

Processus tempus et efficientiam CNC EDM (electrica missionem suam machining) mori mergit machinis Affectantur pluribus factoribus ad apparatus parametri materialia proprietatibus electrode consilio et operational exercitia. Intelligentes haec factores est crucial pro optimizing machining processus, improving productivity et assequendum desideravit results. Hic es key factores qui afficiunt processus temporis et efficientiam CNC EDM mori mergit machinis:

Electrode Material and Design: Material: Alia Electrode Materials (E.G., aeris, Graphite, Tungsten aeris) habent variaing induendum rates et conductivity. Graphite, exempli gratia, habet inferius induendum rates sed requirere magis precise machining conditionibus comparari aeris.

Electrode gere, High Electrode gerunt potest ducere ad dimensional inaccracies et eget crebris Electrode replacement aut rursus machinens, afficiens processus Time.electrode Geometrice, in Area, magnitudine et figura et MRR. Complex or fine-feature electrodes may require longer processing times due to the need for precise control and slower machining speeds.Multi-electrode Strategy: Using multiple electrodes with different geometries (roughing, semi-finishing, and finishing electrodes) can optimize processing times and improve efficiency by adapting the machining strategy to each phase of the process.

Workpiece Material proprietatibus: Material Type: durius et durior materiae (E.G., obduratum ferro, Tungsten carbide) requirere iam processus temporibus debitum ad inferiora MRR et auctus ad gerunt. Softer materials may machine faster but may require careful control to avoid excessive electrode wear.Material Conductivity: Materials with higher electrical conductivity can result in faster EDM processes, while materials with lower conductivity may slow down the process.Material Thickness and Complexity: Thicker and more complex workpieces require longer processing times, especially when intricate features are involved.

Dielectric Fluid and Flushing Conditions:Dielectric Type and Quality: The type (e.g., kerosene, deionized water) and quality of the dielectric fluid affect the gap stability, debris removal, and spark consistency. Contaminari vel degradatus dielectric fluido potest causare erratic obit et tardior machining.flushing efficientiam: propriis rutilant ex obstantia ex scintilla gap est essentialis ponere firmum machining conditionibus. Inadaquat rutilant potest ducere arroganti, brevi circuits, aut pauper superficiem qualis potest extendere processus temporibus.

Machining belli: roughing, semi-consummatione, et consummatione transit: efficient machining strategies involvere per roughing transit ad excelsum MRR et consummatione transit ad consequi desideravit superficies consummavi. Tempus destinatio inter hos transit afficit altiore processus time.Tool iter Optimization: Optimization of Tool.Tool et accedat Anglorum potest minimize non-productive, et superficies in real-tempus ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempus ad Optimise MRR et superficies in real-tempore ad optimize MRR et superficies in real-tempore ad Optimise MRR et superficies in real-tempore ad Optimise MRR et superficies in realis, reducendo ad operatoris MCCC.

Machina conditio et stabilitatem: apparatus rigiditatem et stabilitatem: et mechanica stabilitatem et rigiditatem Edm apparatus ictum praecisione et constantiam. High-qualitas machinis cum stabilis mechanica structurae potest operari ad altiorem celeritates sine sacrificando accurate, reducendo processus time.servomotor responsio et imperium system: et qualis est in Machining et verius potest respondere mutationes in machinarum conditionibus, afficienti potest.

Temperature et environmental factors: Thermal Stabilitatem: temperatus in Workshop potest afficit apparatus accurate et dielectric fluidi proprietatibus, impacting machinans et modum efficientiambientis in optimal et consistere et in modum machining in modum, contribuens et consistent machining in bonis et continet in modum machining et continet et consistent machining in statu, contribuens et consistent machining in bonis et continet in modum machining et continet et consistent Machining perficientur et continet et consistent Machining perficientur et continuam et consistit in Machining Condition:

Optimizing the factors affecting the processing time and efficiency of CNC EDM die sinking machines involves a comprehensive understanding of electrical parameters, electrode and workpiece properties, dielectric conditions, machining strategies, and operator expertise. By Balancing haec factores, manufacturers potest consequi desideravit machining results dum minimizing processus et maximizing altiore efficientiam.